The government heralded, in December 2021, its ambition of fabricating the most sophisticated sub-28 nanometre semiconductor chips in India, committing to subsidise 50 percent of its project cost of fab projects besides providing a host of other support measures. It received one application for fabricating 28-nanometre chips from Vedanta-Foxconn JV. Unfortunately, it did not make any real progress. Foxconn terminated the JV in July 2023.

The government has since lowered its ambition. In October 2022, the government promised a 50 percent incentive for almost all types of semiconductor fabs - 28 nm or larger. American semiconductor major Micron Technology Inc. announced, on 22 June 2023, its plans to build a new semiconductor assembly and test facility (not a chips fabrication facility though). The Union Cabinet approved fiscal support of Rs 11,000 crore for this proposed facility.

What is the state of India’s semiconductor chip programme? Does Foxconn's withdrawal amount to its failure? Or, does Micron's investment signal a revival of the government’s semiconductor chip ambition?

India’s Semiconductor Chips Scenario

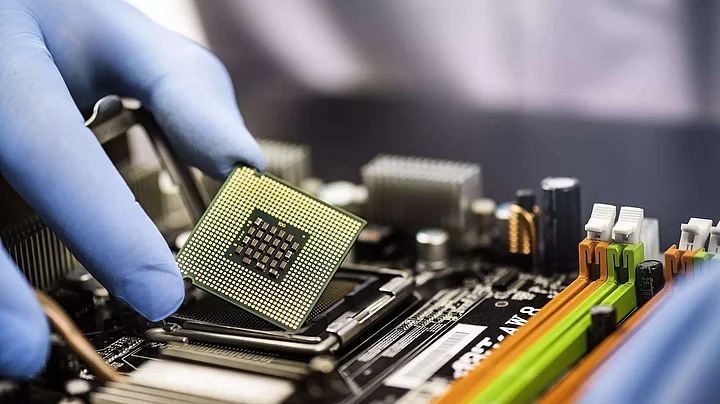

Integrated-circuit chips, fabricated on semiconductors, are the real building blocks and enablers of the Digital Age where the bulk of production, transmission and consumption of goods and services and building of assets takes place on electronic equipment, machines and processes run on semiconductor chips.

The semiconductor chip fab industry has already become $500 billion strong and is heading strongly to reach $1 trillion by 2030. The electronics industry is many times larger. Gradually, the global GDP is going to increasingly ride on semiconductor chips.

India has been virtually nowhere in the semiconductor fab ecosystem. India does not manufacture silicon or any other semiconductor material. It does not have any semiconductor fab worth the name. Many Indians design semiconductor chips for global companies, in their development centres abroad and also those set up in India. Many Indian companies use semiconductor chips for manufacturing their relatively low-tech equipment and products.

India has a demand for semiconductor chips, and has a lot of talent to design chips. But, India does not make semiconductor materials or fabricate chips.

Modi Government’s Mega Semiconductor Push

Indian governments have been rooting for their semiconductor fab ambitions for long but not succeeding. Manmohan Singh's government formulated a semiconductor policy and offered major sops costing about Rs 39,000 crore. Two proposals- one from the Jai Prakash group, along with IBM and the other from the HSMC- came but died a slow death.

Modi's government’s plan was more ambitious to make India a semiconductor fabrication hub of the world. The Government issued four notifications, in December 2021, to incentivise semiconductor chip fabrication and design in the country putting fiscal support of Rs 76,000 crores (at that time $10 billion) on the table.

The main notification invited companies/consortia / JVs to set up silicon CMOS-based semiconductor fabs in India for manufacturing logic, memory, digital ICs, analog ICs and some other kind of chips promising graded fiscal support ranging from 30 percent to 50 percent of the project cost. The pride of place was reserved for sub 28 nm chips which were promised 50 percent of the cost as an incentive.

Other notifications invited proposals for setting up in India for manufacturing display fabrication units/ panels (50 percent incentive), compound semiconductors, silicon photonics, sensors, etc. (30 percent incentive) and encouraging chip designing by domestic companies, startups, and MSMEs etc. (50 percent of the eligible expenditure subject to a ceiling of Rs 15 crores per application).

With additional support from state governments, fiscal subsidies were expected to range from 40 percent to 70 percent of the capital cost. Other incentives were also offered including support for the development of infrastructure / common facility centre under the modified electronics manufacturing clusters (EMC 2.0) scheme. The government also promised purchase preference in procurement under the Public Procurement (Preference to Make in India) Order 2017.

It is not unreasonable to believe that about 80 percent of the cost of the semiconductor fab project for sub-28 nanometre chips would have come from the government under this myriad package of subsidies and support.

Government’s Ambitions Have Come Unstuck

MEITY reported, in its 2022-23 Annual Report, that five (5) applications were received for Semiconductor and Display Fabs, with a total investment to the tune of $20.5 billion (Rs 153,750 crores). In addition, two (2) applications were received for Semiconductor Packaging Units and sixteen (16) applications for the Design Linked Incentive Scheme. None of the applications, except five small chip design applications, were approved.

Three consortiums- Vedanta Foxconn, IGSS Ventures and ISMC- made applications to set up semiconductor fabs to manufacture Si CMOS chips and invest an estimated amount of $13.6 billion. They sought fiscal support of about $5.6 billion.

Vedanta-Foxconn JV promised to set up a 28-nanometre fab and asked for an estimated $3.7 billion in fiscal support. None of the principal partners had any semi-conductor chip fabrication experience though Foxconn is the largest electronic products manufacturer/assembler in the world. The JV failed to locate a fab-manufacturer partner or a technology- supplier. Though the project received approval from the Gujarat government and an MoU was signed in Dholera in the presence of IT Minister Vaishnav, the project proposal stalled with Foxconn finally exiting the JV.

The other two made still non-descript progress. The ISMC Consortium, promoted by Abu-Dhabi-based Next Orbit Ventures, had wanted to fabricate analogue chips (65 nanometres and higher). IGSS Ventures, a Singapore-based investment holding company, also wanted to fabricate chips of 65 nanometres. Two proposals were received for fabricating the display chips- one from Vedanta and the other from Elest with Rajesh Exports, as its partner. These proposals also did not make any progress. The ambitious semiconductor chip fabrication programme, announced with big fanfare, had by and large come unstuck.

Government Lowers the Ambition and Regroups

Looking at very little enthusiasm for sub-28 nanometre chips, the government decided to change tack. The scheme was reframed and four new notifications were issued in October 2022 and later providing uniform fiscal support at 50 percent of project cost for all types of chip fabs. These notifications also advise the earlier applicants to apply afresh effectively intimating shelving of all earlier applications, barring the 5 approved.

The government also issued in November 2022 comprehensive guidelines for three components:

Principal chips - logic, memory, digital, analog etc

Display fabs

Chip designing scheme

The guidelines for the fourth component - compound semiconductors - were issued in June 2023.

Still not sure of what the response this time would be, the government initiated a fresh round of applications on 31 May 2023 for setting up semiconductor and display fabs as per the Modified Semicon India Programme. This time, no specific short period was prescribed for applications. This would be on a tap basis and open until 31 December 2024.

Unsaid in the modified programme and invitation for application is the acceptance that there is no expectation of anyone offering to set up sub-28 nanometre chip fabrication plants. It seems the government is reconciled to receive proposals for less sophisticated semiconductor fabs.

Micron Technologies application is perhaps the first one to apply. The government was quite prompt in approving it with an allocation of Rs. 11,000 crores of fiscal support though it is only a packaging and testing facility.

Is Semiconductor Fab Chase Worth Fiscal Cost and Effort?

There are three principal arguments for domestic manufacturing of industrial products, which also apply to semiconductor fabs.

First, to produce products at lower prices using the comparative advantage of lower labour costs and available natural resources. Second, to add value domestically to contribute to higher GDP. Third, to generate employment.

The semiconductor chip fabrication in India programme, though, is unlikely to secure any of these three advantages. The Semiconductor programme did not ask for, and no bidder promised, that the semiconductor chips would be sold in India to the Indian electronics products manufacturers at prices lower price than global prices despite 50 percent to 70 percent fiscal support. The fact that two bidders in the earlier round proposed to export almost the entire semiconductor chips produced also negated the possibility of Indian electronic manufacturers getting the chips produced in India at lower than prevailing prices.

Semiconductor chip fabrication is highly capital-intensive. Chip designing is highly technical and design talent intensive. Chip fabrication is done using ultra-precision and highly sophisticated technologies, completely autonomously. In this eco-system, there is next to nothing direct employment in semiconductor chip fabrication.

Hardly any of the silicon or other materials or machines/tools needed for chip making was envisaged to come from India. There would have been very little domestic value addition in such a case.

In the circumstances, it is worth considering seriously whether there is any real economic advantage for India in investing so much public money and making so much effort in establishing semiconductor fabs. On the contrary, the US, China, Japan and many other countries are pumping in so much in semiconductor subsidies that it is quite likely that there would be a glut of semiconductor chips in times to come, which will make these chips relatively quite cheap to buy and to build products and services thereon.

(The author is former Economic Affairs Secretary and Finance Secretary of India. This is an opinion piece and the views expressed above are the author’s own. The Quint neither endorses nor is responsible for the same.)